Ctrl-P

Machine learning to optimise 3D print processes

Additive Manufacturing (AM), or 3D printing, has the potential to transform production chains by enabling complex, tailor-made products to be produced on demand, with minimal waste and without costly tooling. Yet despite rapid advances in materials, hardware, and software, one fundamental bottleneck remains: the translation from a digital design to machine instructions still depends heavily on human expertise and trial-and-error. Currently, optimal print settings are discovered only after repeated adjustments, which makes the process slow, inefficient, and wasteful.

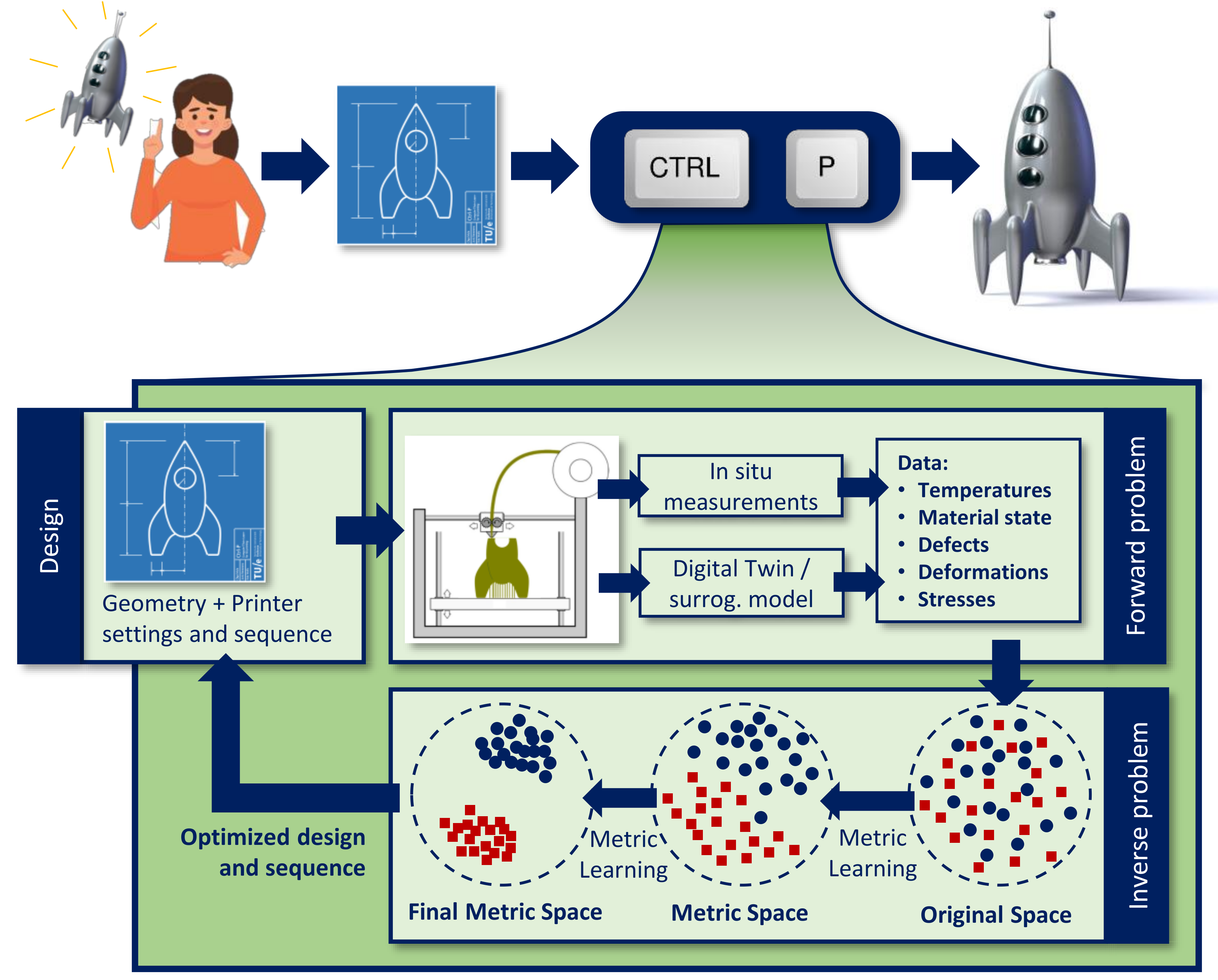

This project aims to make controlling a 3D printer as straightforward as printing a paper document: as simple as pressing Ctrl-P. Our vision is a fully automated pipeline that converts a digital drawing directly into reliable printer instructions, producing objects with optimal mechanical and geometrical properties in a single run. To achieve this, we will develop a Digital Twin of the printing process: a virtual model that integrates physics-based simulations, sensor data, and historic printing records. Combined with data-driven learning, this twin will allow us to predict how process settings affect the final product, and to automatically select the optimal strategy.

The project will not only deliver practical tools for industry but also address fundamental scientific questions. At its core lies the challenge of describing and controlling the evolution of shapes under physical constraints—a problem that connects advanced manufacturing to fields such as evolutionary biology and anatomical growth. By building mathematical and AI-based methods to tackle this problem, we contribute to both engineering and fundamental science.

Through collaborations with industrial partners and the Eindhoven AI Systems Institute (EAISI), this project will position TU/e at the forefront of user-centered technological design. Its outcomes promise more sustainable production, reduced waste, and a leap toward first-time-right manufacturing.

| Ctrl-P: Compute-TRain-Learn 3d Printing | |

| Funding | EMDAIR (Eindhoven Artificial Intelligence Systems Institute) |

| Years | 2023- |

| PhD-candidate | Ruben Schmeitz and Benjamin Caris |

| Supervisors | Joris Remmers, Rob Wolfs, Olga Mula, Rafael Bailo |