3D metal printing in aerospace

Model based process parameter optimization in Laser Powder Bed Fusion for improved process control

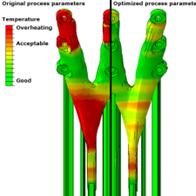

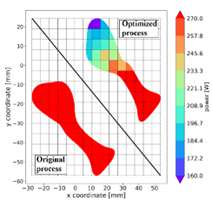

3D printing (or additive manufacturing) is a manufacturing process which is gaining popularity within the aerospace sector thanks to the possibilities offered by this technology to manufacture highly optimized and efficient, lightweight structures. In the Laser Powder Bed Fusion (LPBF) process, a laser selectively heats and melts powder in a powder bed. The stability of the LPBF process is strongly dependent on the printed geometry. Variations in microstructure and properties observed in the same product are caused by variations in thermal history of the L-PBF process. To be able to prevent these variations, an accurate prediction of this multiscale process is required. For this, phenomena on the temporal and spatial scale of the melt pool (<1ms and <0.2 mm), as well as on the scale of a complete part (>10 hours and >10 cm) should be captured. Analytical and finite element models on these different spatial and temporal scales are available.

The goal of this assignment is to develop and implement innovative modelling methods with the goal to optimize the LPBF process at multiple temporal and spatial scales. Combinations of Finite Element, Analytical and machine learning models will be investigated to significantly improve computation time allowing for practical applications of process optimization strategies. An initial framework is available in Python, which can be expanded to include more intelligent methods for adjusting the LPBF process for a more stable and predictable component. To verify the modelling methods and process optimization strategies, experiments have to be designed using an LPBF system with state of the art thermal monitoring systems.

This assignment will be performed within the Metal Additive Manufacturing Technology Centre (MAMTeC) which is part of the Royal Netherlands Aerospace Centre (NLR) located in Amsterdam and Marknesse.

| 3D metal printing in aerospace: model based process parameter optimization in Laser Powder Bed Fusion for improved process control | |

| Supervisor | Hans van Dommelen, Joris Remmers |

| External supervisor | Tim Koenis (NLR) |

| Exp./Num./Design | Numerical |

| Starting date | September 2025 |