Advancing the Mesh

Enhancing Finite Element Tools for Additive Manufacturing

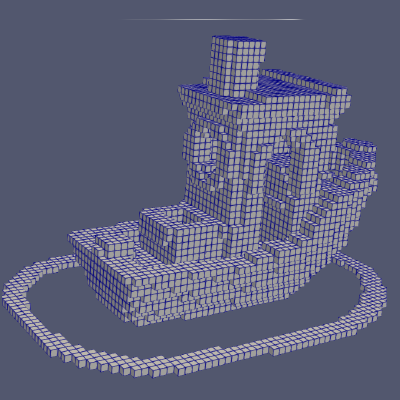

This student project offers an opportunity to contribute to the ongoing development of a tool that converts G-code instructions into finite element meshes, a key step in simulating additive manufacturing processes. The existing tool, developed in a previous project, is tailored for Fused Filament Fabrication (FFF) printers like the Ultimaker and accounts for specific machine characteristics such as jerk, providing realistic simulation inputs.

Your work in this project will focus on three main areas of improvement:

- Handling G-code for Belt Printers: Expand the tool’s functionality to accommodate the unique requirements of belt printers, which operate differently from standard FFF machines.

- Performance Optimization: Enhance the tool’s efficiency and speed, ensuring it can process more complex and larger-scale tasks effectively.

- Graphical User Interface (GUI): Create a user-friendly GUI, making the tool accessible to a wider range of users, including those with limited programming experience.

Ultimately, the refined tool will be integrated with an in-house developed finite element solver to enable detailed and realistic 3D printing simulations. This project is a valuable opportunity to apply your skills in Python programming and computational modeling, contributing to advancements in various ongoing research projects in the field of additive manufacturing.

| Advancing the Mesh: Enhancing Finite Element Tools for Additive Manufacturing | |

| Supervisor | Joris Remmers |

| Exp./Num./Design | Numerical |

| Starting date | September 2025 |